A loaded waste container at the site of the former Plutonium Finishing Plant is surveyed to ensure that it is safe for transfer to Hanford’s on-site disposal facility. (Photo: DOE)

Final cleanup activities at the Hanford Site’s demolished Plutonium Finishing Plant have resumed following a pause in work prompted by the COVID-19 pandemic, the Department of Energy announced. Crews with the DOE’s Richland Operations Office and site contractor Central Plateau Cleanup Company will remove, package, and dispose of rubble remaining from the demolition of the plant’s plutonium reclamation facility, which was torn down in 2017.

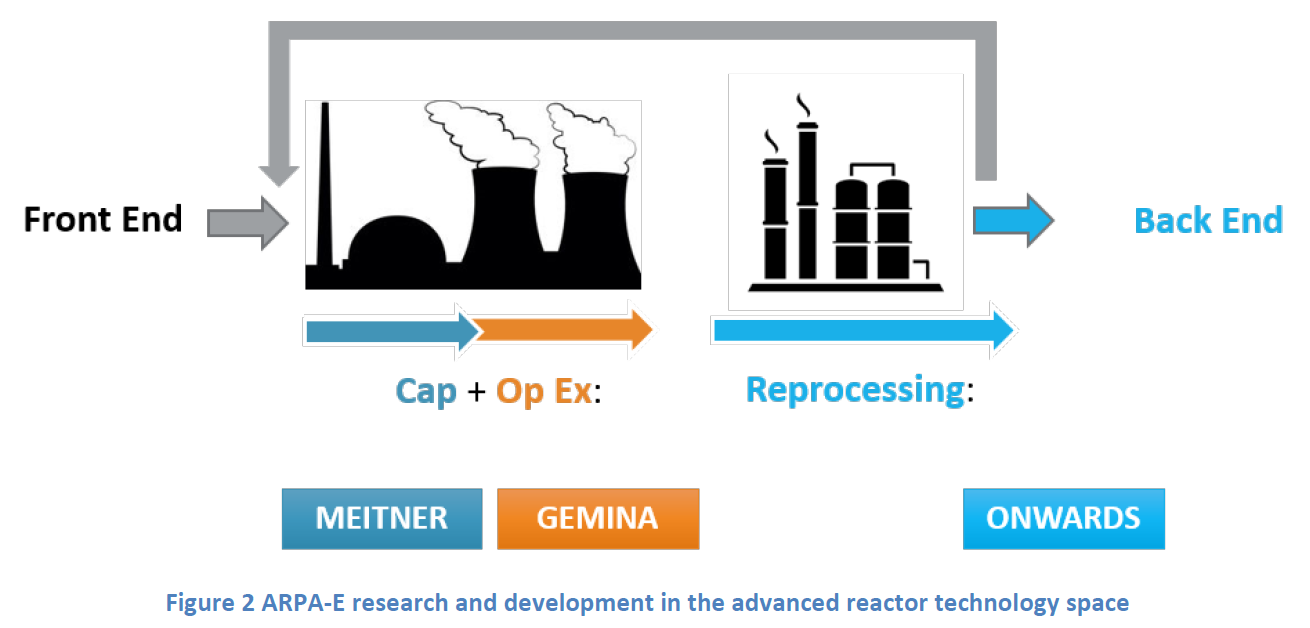

This figure, included in the ONWARDS funding opportunity announcement, shows how ARPA-E R&D programs address different stages of advanced reactor development. (Figure: ARPA-E)

The Department of Energy has announced up to $40 million in funding for a new Advanced Research Projects Agency-Energy (ARPA-E) program to conduct research and development into technologies for reprocessing and ultimately disposing of used nuclear fuel. The program, “Optimizing Nuclear Waste and Advanced Reactor Disposal Systems” (ONWARDS), announced on May 19, targets both open (once-through) and closed (reprocessing) fuel cycles to reduce the amount of waste produced from advanced reactors tenfold when compared to light water reactors.

Using Framatome’s technology, Germany’s VIRERO project is developing a robotic system for sorting and packaging radioactive waste. (Photo: Framatome)

Paving the way for increased automation in nuclear decontamination and decommissioning and waste management, French nuclear company Framatome announced that testing has confirmed the operation of its robotic systems for handling and sorting high-dose waste components.

A deposition tunnel is excavated into bedrock at Finland’s Onkalo facility. (Photo: Posiva)

Posiva Oy, the company responsible for the disposal of Finland’s spent nuclear fuel, announced last week that it has begun excavating the first disposal tunnels at the Onkalo deep geologic repository near the Olkiluoto nuclear power plant.

Ray Geimer with DOE contractor Central Plateau Cleanup Company, left, shows company president Scott Sax a mock-up of parts of a vertical pipe casing system at Hanford’s Maintenance and Storage Facility. Photo: DOE

Workers at the Department of Energy’s Hanford Site near Richland, Wash., recently completed testing a mock-up of a system that will be used to isolate and stabilize about 15,000 pounds of radioactive debris in the site’s K West Reactor spent fuel storage basin.

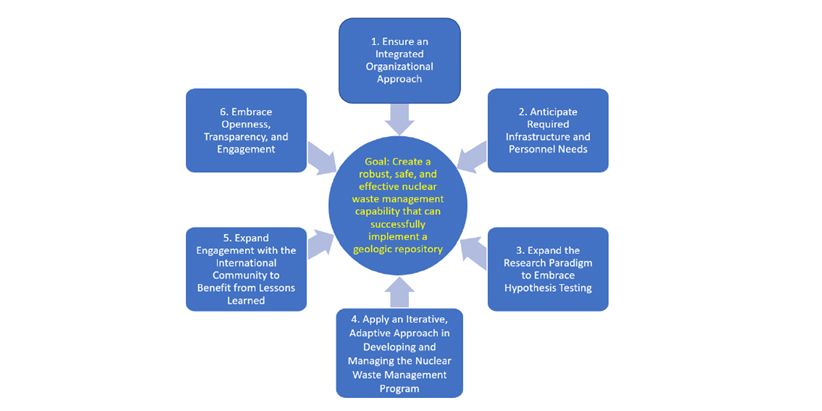

The NWTRB’s six overarching recommendations for the DOE’s nuclear waste management program.

An illustration of WIPP’s Safety Significant Confinement Ventilation System, expected to be completed in 2025. Image: DOE

Nuclear Waste Partnership (NWP), the management and operations contractor for the Department of Energy’s Waste Isolation Pilot Plant in southeastern New Mexico, announced that it has awarded a subcontract valued at approximately $163 million to The Industrial Company (TIC) to complete the construction of the transuranic waste repository’s Safety Significant Confinement Ventilation System (SSCVS).

Waste handlers take radiological readings as a crane lifts containers from a TRUPACT-II cask in the contact-handled waste bay at WIPP. Photo: DOE

The Waste Isolation Pilot Plant in southeastern New Mexico is once again accepting shipments and processing transuranic waste following a two-month annual maintenance outage. According to the Department of Energy, WIPP is back to accepting five waste shipments per week, with post-pandemic plans to increase shipments to 10 per week.

A retired USGS geologist shares his experience of working on the publicly misunderstood nuclear waste repository and its geology.

The author on a typical day at Yucca Mountain, with Solitario Canyon and the flat-topped repository block seen in the background.

A radiological worker surveys the inside of a TRUPACT-II containment lid during waste handling operations at WIPP. Photo: DOE

Dry cask storage at the closed San Onofre Nuclear Generating Station in Southern California. Photo: Southern California Edison

Saying they are cautiously optimistic that the Biden administration can change the U.S. trajectory on nuclear waste, some Stanford University experts have offered their recommendations on how it can be done in a recent Stanford news posting.

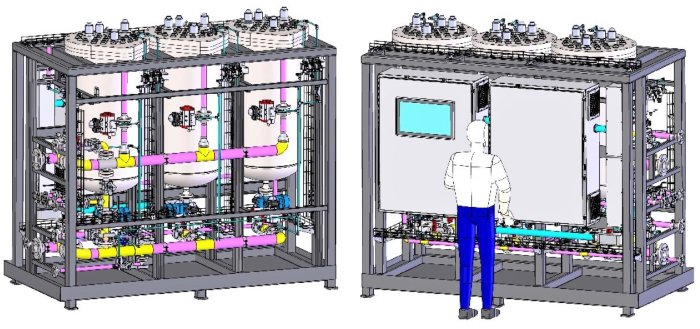

A front-and-back illustration of the new Hanford ETF filter system, which is intended to eliminate the need to shut down operations every 12 hours to replace filters during wastewater processing. Image: DOE

A new wastewater filter system being installed at Hanford’s Effluent Treatment Facility (ETF) is expected to increase waste processing throughput, improve efficiency, and save money as the site in southeastern Washington gears up to treat tank waste, the Department of Energy announced.

Holtec’s proposed HI-STORE interim storage facility. Image: Holtec

New Mexico attorney general Hector Balderas has filed suit against the Nuclear Regulatory Commission and the United States, seeking to stop Holtec International’s application to build and operate its HI-STORE consolidated interim storage facility for used nuclear fuel in the state. The complaint, filed in the U.S. District Court of New Mexico on March 29, seeks a declaratory judgment that the NRC is acting beyond the scope of its authority and an injunction preventing the licensing from moving forward.

Savannah River’s DWPF has been pouring high-level waste canisters for a quarter of a century. Photo: DOE

The month of March marked the 25th year of radiological operations for the Defense Waste Processing Facility (DWPF) at the Department of Energy’s Savannah River Site in South Carolina. Radiological operations at DWPF, which is used to treat Savannah River’s high-level radioactive tank waste, began on March 12, 1996, with the first canister of vitrified waste poured on April 29 that year.

To date, more than 4,200 stainless steel canisters of vitrified waste have been poured at DWPF, according to the DOE.

The only operating waste vitrification plant in the nation, DWPF is operated by Savannah River Remediation, the DOE’s liquid waste contractor at the site. According to the DOE, DWPF operations are expected to continue for approximately 15 more years, and about 4,000 more canisters are scheduled to be produced. The DOE expects to begin hot operations at a second waste vitrification plant later this year at its Idaho National Laboratory site.